NEMA23 Closed-Loop Stepper motor 2.2N.m 320oz.in 101mm Encoder kit

Couldn't load pickup availability

-

Package include :

1 X NEMa23 2.2 nm closed loop stepper motor.

1X HBS57 Stepper motor driver.

1X 5m Encoder cable .

1X 5 m stepper motor .

1X 1m 2core DC power cable .

Nema 23 closed loop stepper motor is a bipolar stepper motor used in CNC machine, drawing equipment and sewing machine, robot arm, etc. It is a four-wire connection motor with encoder, holding torque at 2.2N·m, step angle accuracy ±5%, no lost step and high precision.

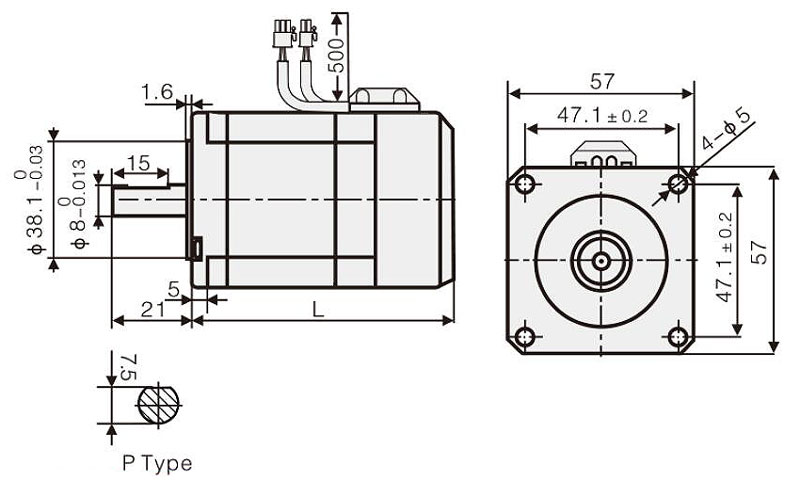

Physical Specification

- Flanged Size: 57 x 57mm (Nema 23)

- Motor Length: 102mm

- Shaft Diameter: 8mm

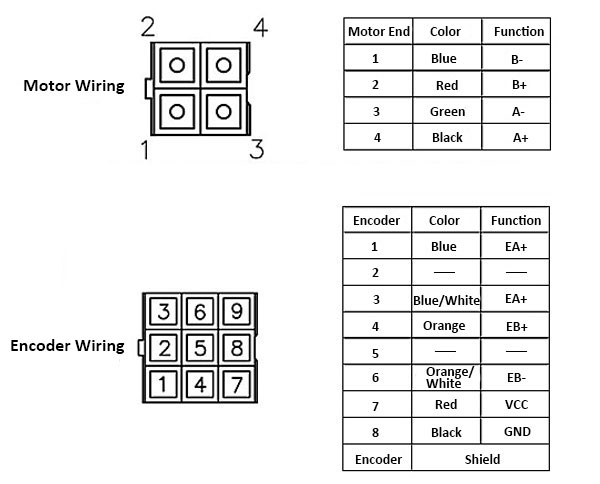

- Number of Leads: 4 wire

- Weight: 1.1kg

Electrical Specification

- Motor Type: Bipolar Closed Loop Stepper

- Step Angle: 1.8°

- Rated Current: 5.2A

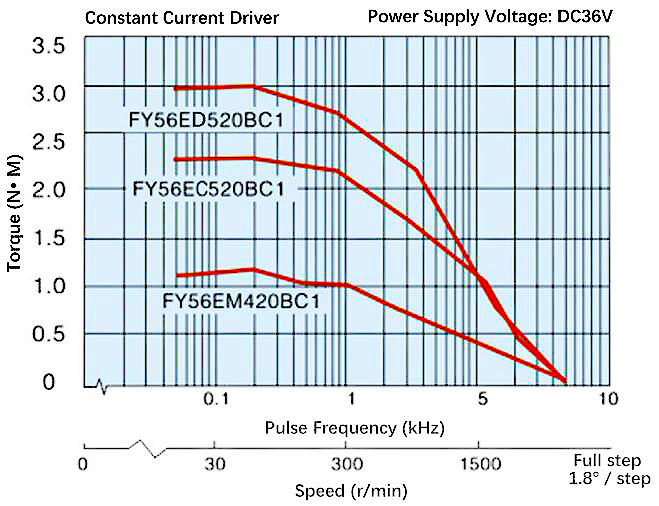

- Holding Torque: 2.2 N·m (220N·cm, 311.5 Oz.in)

- Phase Resistance: 0.42Ω

- Phase Inductance: 1.9mH

- Rotor Inertia: 520g·cm2

Dimensions (Unit: mm)

L=102mm

Motor & Encoder Wiring Diagram

Speed-Torque Curve Diagram

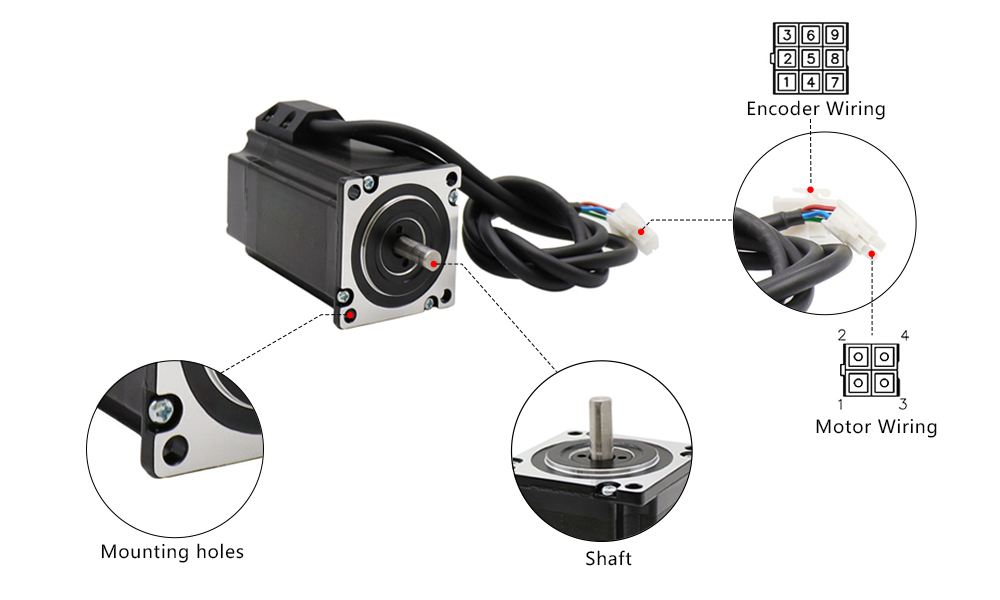

Details

Tips: Stepper motors must be equipped with motor drivers to work

The permanent magnet stepper motor cannot be directly connected to the frequency AC or DC power supply like DC motor and AC motor. It must be equipped with a dedicated stepper motor driver to work. Because the stepper motor is composed of pulse generation control unit, power drive unit, protection unit and so on, the conventional application cannot be realized in terms of structure and principle.

The drive unit of the stepper motor must be directly coupled with the stepper motor driver to ensure electromagnetic interference, so that the electronic circuit can be used to change the direct current into time-sharing supply, and the multiphase timing control current. That is, the stepper motor must have a driver to supply power.